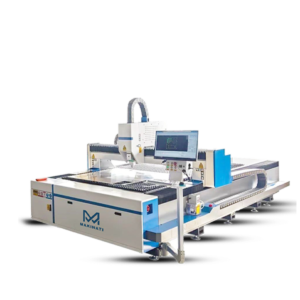

CNC Router 1325 Main Parts of the Machine:

CNC router is a computer-controlled cutting machine used for cutting various hard materials, such as wood, composites, aluminum, steel, plastics, and foams.

| 1 | Spindle | 6.0KW HSD Air Cooling Spindle |

| 2 | Control System | OriginalA11 DSP Control System |

| 3 | Driving Motors and

Drivers |

X-Axis: High-Speed 110A Stepper Motor+YAKO2811 Driver |

| YAxis: High Speed 110 Stepper Motor+YAKO2811 Driver + Double Reducers | ||

| Z Axis: High Speed 110 Stepper Motor+YAKO2811 Driver | ||

| 4 | Ball Screw | High Precision Taiwan Designed Ball Screw |

| 5 | Rails | High Precision HIWIN Square Rails 25mm |

| 6 | Blocks | High Precision HIWIN Blocks 25mm |

| 7 | Rack and Opinion | HighPrecision Taiwan Designed Helical Tooth |

| 8 | Machine Structure | HeavyDutyStructure and Strong Structure (Double Strengthened Structure) |

| 9 | Spindle quantity | One Spindle |

| 10 | WorkingTable | T-slot and Vacuum Combined Working Table |

| 11 | Electronics | Original France Schneider Brands |

| 12 | Tool Sensor | Included |

CNC Router Parameter:

|

|

Max. engraving area | 1300*2500*220mm |

| 2 | Acceptable material

thickness |

220mm |

| 3 | Working table | T-slot Working Table |

| 4 | Vacuumpump | / |

| 5 | Working table size | 1300mm*2500mm |

| 6 | Processing resolution | ±0.1mm |

| 7 | Re positioning resolution | ±0.02mm |

| 8 | Spindle motor | Original 6.0KW HSD Air Cooling Spindle |

| 9 | Spindle rotating speed | 18000rpm |

| 10 | Transmitting system | XY axis Rack and Opinion+ Square guide; Z axis ball screw+ Square guide |

| 11 | Power consumption | 2.0KW(Without Spindle) |

| 12 | Driving Motor | High Speed 110 Stepper Motor + YAKO 2811 Driver |

| 13 | Empty Traveling Speed | ≥40000mm/min |

| 14 | Processing Speed | ≥20000mm/min |

| 15 | Spindle Quantity | 1 spindle |

| 16 | Control system | A11 DSP Control System (Original Brand) |

| 17 | Format | G code |

| 18 | Voltage | 3 Phase 380V, 50HZ |

| 19 | Surroundings | Temperature: 0-45℃; humidity:30%-75% |

| 20 | Net Weight | 1350KG |

| 21 | Packing Size | 3050mm*2200mm*1900mm |

CNC Router Key Features:

CNC Router Control System:

CNC Router for precise and automated operation

- Cnc Router Spindle: The cutting tool, often a high-speed rotating spindle that can hold different types of bits

- Cnc Router Working Area: Varies by model, common sizes include 600×900 mm, 1300×2500 mm, and larger

- Materials: Wood, MDF, plywood, aluminum, brass, plastics, foam, and composites

- Software: Compatible with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software like AutoCAD, Fusion 360, VCarve, and others

When considering a CNC router, firstly you need to evaluate the key specifications. For example, the working area is crucial as it defines the size of the projects you can handle. In addition, spindle power plays a significant role since it impacts the router’s ability to cut through different materials. Moreover, the spindle speed should be adjustable so that it can be optimized for various tasks.

However, it is not just about the machine’s capabilities. Additionally, the control system must be user-friendly and compatible with your design software. Therefore, checking if the controller supports your preferred software is essential. Furthermore, the accuracy and precision of the router are fundamental because they determine the quality of the final product.

Consequently, when selecting a CNC router, make sure to also consider the frame construction as well as the drive system. Ultimately, if you choose a machine with robust features and good support, you’ll find that it enhances your productivity and precision over time.

In addition, having an adjustable spindle speed allows for versatility since it can be tailored to different tasks.

However, it’s not only about the machine’s power. Furthermore, the control system should be user-friendly and compatible with your design software. Therefore, verifying whether the controller supports your preferred software is crucial. Besides, the accuracy and precision of the router are critical because they determine the quality of your finished product.

Consequently, it is necessary to consider both the frame construction and the drive system when choosing a CNC router. Ultimately, if you opt for a machine with robust features and strong support, you will find that it enhances your productivity and precision in the long run.

Why Choose CNC Router

In the world of CNC routers, selecting the right machine can be a game-changer for your business. Firstly, consider the material compatibility of the router. For instance, whether you need to work with wood, metal, or plastics, ensuring the router can handle those materials is crucial. Furthermore, the size of the router’s bed is significant, as it will determine the maximum dimensions of the items you can produce.

Additionally, the type of control system that comes with the router should meet your needs. While some machines offer advanced control options, others might be more basic but sufficient for simpler tasks. Consequently, evaluating the software compatibility is important since it will affect how easily you can integrate the router into your existing workflow.

Reviews

There are no reviews yet.